Design and Engineering

Spicoly Plastics’ design and engineering processes are crucial in generating innovative products, optimising engineering processes, and ensuring the highest standards of product quality and performance.

We offer leading concept development services, which entail planning and developing a tailored, original concept. Our team of professionals generates comprehensive 3D drawings of your concept, and if approved, we also provide internal manufacturing of a 3D-printed model.

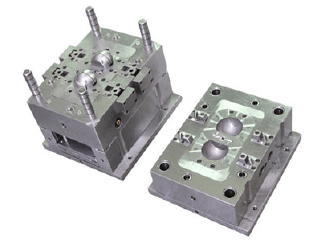

This process is then followed by mould design, which includes creating and manufacturing a steel mould to match the approved concept. Once we obtain the necessary raw materials, we will start with production, followed by marketing and feedback.

Continuous refinement and improvement are a critical component of our approach at Spicoly Plastics’, a process that is strictly adhered to after your product is released to ensure continued market success.

Our design and engineering activities include the following:

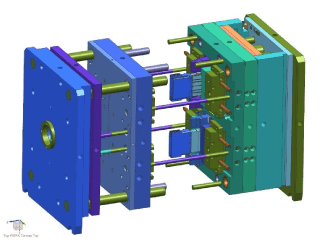

- Computer-Aided Design (CAD): We use CAD software to precisely and efficiently create plastic models, which allows us to accurately envision and refine ideas.

- Computer-Aided Engineering (CAE): Our CAE technologies enable us to study and simulate the performance of plastic components before they are manufactured, ensuring precise functionality.

- Rapid Prototyping: We use 3D printing technology for efficient prototyping, allowing us to iterate and test concepts before final manufacturing.

- Mould Design and Simulation: Advanced mould design and simulation software allows us to optimise the injection moulding process, enhancing quality and efficiency.

- Material Selection and Testing: We carefully choose engineering plastics of the highest quality and thoroughly test them to guarantee that they fit specifications.

- Quality Control and Inspection: Automated inspection systems, such as vision systems and coordinate measuring machines (CMMs), are used to ensure components are dimensionally accurate and/or to discover potential flaws.

- Process Monitoring and Optimisation: We monitor production operations in real time, recording factors such as temperature, pressure, and cycle time, to maintain consistency and identify potential errors early.

- Sustainability Considerations: We are devoted to integrating sustainability into our engineering procedures. This involves employing eco-friendly materials, designing with recyclability in mind, and minimising waste during production.

Spicoly Plastics designs and manufactures products to meet client specifications while providing expert advice on technology and techniques. During the design phase, our team analyses all risk considerations and then chooses materials supplied by qualified suppliers who adhere to ISO standards and Standard Operating Procedures (SOPs).

Comprehensive testing of products ensures safety and compliance, while final inspections eradicate errors. In addition, our team of experts ensures that products are meticulously recorded and remain traceable.

While we have a talented in-house team of designers and engineers, we also outsource design and engineering as necessary to ensure our clients receive the leading industry knowledge and expertise found on the market. Spicoly Plastics’ dedication to quality in design and engineering drives our growth and adds long-term value to our clients.